Low Temperature Rolling Technology of SBQ Special Steel Bar Rolling Mill

1. Preface

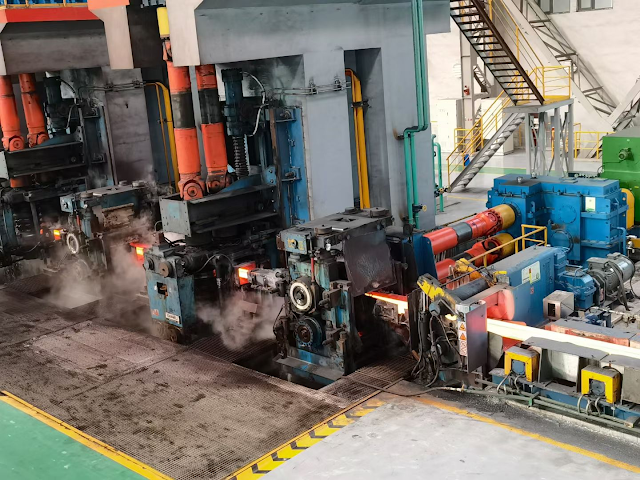

The bar rolling mill with the most advanced low temperature rolling (LTR) process built by Hani tech has been running smoothly since it was put into operation in early 2006, and has already reached full capacity, achieving good production performance and application effect. No. 1 SBQ special steel bar rollinhmill RM1 is part of the largest construction project implemented by Hani Tech in China. The project also includes the second set of Danieli "twin" bar mill RM2, which is specially used to produce ordinary steel deformed steel bars. It is arranged in the span adjacent to RM1 and installed and commissioned simultaneously with RM1 mill.

Danieli has carried out a lot of experimental research to reduce the material hardness of medium and low alloy steels, especially all steel grades that require good shear properties and are prone to cracks due to excessive hardness and stress concentration. For stainless steel production, many experimental studies have also been carried out to improve the mechanical properties of hot rolled materials for some specific purposes. In order to control the performance indexes of materials, such as hardenability and toughness, how to change the grain size and austenite transformation structure of materials has also attracted great attention.

2 . Overview of Steel Plant

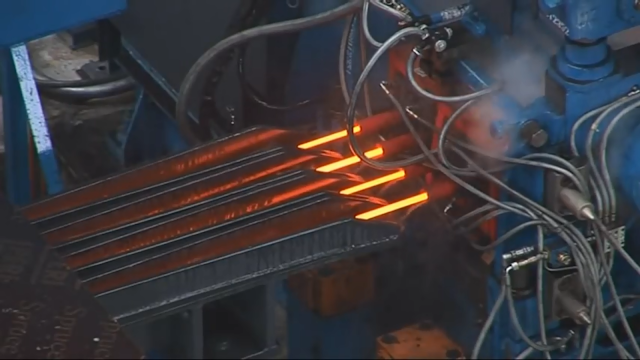

The newly built No. 1 SBQ special steel bar mill RM1 (and its "twin" bar mill RM2) is an 18 stand mill with horizontal / vertical arrangement and looper control function. Two water cooling tanks are arranged between No. 14 and No. 15 racks, and a suitable distance is reserved to make the surface temperature of rolled pieces uniform. Due to this arrangement, the whole temperature drop can be controlled within 260 ℃ without affecting the product surface quality (such as local undercooling) and phase transformation. Selecting a cooling tube with high heat exchange coefficient can make the rolled piece obtain uniform cooling in the cross section. The DSC metallographic structure control system controlled by PLC can ensure that the appropriate setting parameters of the water cooling box can be obtained to make the rolled piece cool evenly in the length direction. The inlet and outlet pyrometers are used to monitor the actual temperature of rolled pieces and modify the basic parameter settings in real time when necessary.

After adopting this advanced technology, the process parameters of the heating furnace can be flexibly adjusted according to the production process needs of different steel grades or due to the long rolling cycle without changing the finish rolling temperature.

3. Product Outline

Hani Tech's SBQ special steel bar rolling mill plant has 160 billets × 160mm square billet, billet weight 2350kg. When conventional rolling is adopted, the maximum production capacity of the rolling mill is 150 t / h; When low temperature rolling is adopted, the production capacity is 100 t / h. Product is ф 16mm~ ф 60mm diameter high-quality round steel bar. The main steel grades and product specifications produced by SBQ special steel bar rolling mill of Hani Tech company.

4. Production Process

The Rolling temperature is one of the three basic rolling parameters. It will affect each stage of grain refinement in the whole process of thermal deformation.

Grain refinement and grain growth control are the main means of low temperature rolling process. It can affect the time temperature transition curve (such as the position of CCT curve), change the length of grain boundary and change the nucleation position. In particular, temperature is the most important thermodynamic parameter affecting the whole rolling process

Formula (a) gives the influence law of temperature. It can also explain the role of the previous grain size in the grain growth process; And how all material deformation directly affects the final grain size in the low-temperature rolling process.

Tdrex=K1 × ln(——) × dck2 × eu × ek3

(a)

In the formula, K1, K2 and K3 are constants, and the value depends on the rolled steel.

The grain refinement process can be divided into different stages, although different stages may also occur at the same time. The deformation of the original grain will increase the dislocation density, and the nucleus can be formed at the boundary of the new grain. The disappearance and regeneration of new grain boundaries are closely related to the actual temperature. The formation and growth of new grains is a thermodynamic process.

At different stages, recovery, static recrystallization and dynamic recrystallization will occur, which will affect the flow stress curve. Finally, grain growth shows a trend of minimizing grain boundary energy. The critical temperature determines the boundary between grain refinement conditions and fully recrystallized grain growth structure. With the decrease of carbon content, this effect will become more obvious. For steels such as 16mncr, the microstructure with grain refinement of more than 40% can be easily obtained.

It is very important to maintain the temperature in the whole rolling range. In particular, when the surface temperature of the rolled piece is lower than the critical temperature and the core temperature is still in the high temperature range, it is possible to form a non-uniform final structure, including grain size and phase composition. More vigorous forced cooling in a water tank will likely form a quenching and tempering layer, which will affect the final quality of the material. If the temperature difference between the material surface and the core is too large due to out of control, a non-uniform grain structure will be produced; During the final heat treatment, the mechanical properties of the material exceed the specified range.

During the test, 30 billets were rolled for each steel grade, and two different temperature ranges were used. The final cooling under these two steel grades and two different conditions is realized by natural cooling, but after the last stand rolling, two different cooling methods are adopted. Take three samples from each rolled piece. One is used for hardness testing and microstructure evaluation in rolling state; The other two are used for heat treatment test.

The cooling curve of the rolled piece on the rolling mill cooling bed affects the mechanical properties of the final material. Because once the CCT curve is determined according to the chemical composition and grain size of the steel, only the cooling route is fixed; The final organization depends on the intersection with the CCT curve. In this case, there is no need to use a cooling bed cover to delay the phase transition process.

5. Heat Treatment

During the test, especially for 60Si2Mn spring steel, many tests have been carried out to optimize the austenite transformation temperature. The amount of ferrite structure and initial grain size in the rolled material are fully considered in the test. In fact, on the one hand, the ferrite structure is suitable for cold shear without cracks in the shear process; On the other hand, it requires full attention to the austenite before quenching. If the phase structure is not handled properly, it is possible to retain the island ferrite structure after quenching, so as to reduce the mechanical properties of the final material.

The target hardness after 40Cr quenching is determined as 52hrc; The target hardness of 60Si2Mn after quenching is 60HRC. In both cases, the national standard requires oil as the quenching medium. According to the national standard, three samples need to be processed in the heat treatment furnace in the laboratory. After tempering treatment, select air cooling mode to cool the sample to room temperature.

6. Microstructure Analysis

The microstructure test results of 40Cr show that the material rolled at low temperature by LTR has very uniform ferrite / pearlite structure; The ferrite phase is more than 30%. In hot rolled products, the ferrite phase only appears near the grain boundary in the form of pre eutectic phase.

For 60Si2Mn, a higher finish rolling temperature is selected, in which the ferrite phase is more similar to the eutectic structure. In any case, if LTR low temperature rolling is compared with conventional hot rolling process, obvious difference can be seen. This is not only reflected in the grain size (from grade 9 to grade 8), but also in the distribution of microstructure. Uniform cooling can not only ensure uniform microstructure in the cross section, but also avoid coarse grains.

7. Conclusion

The SBQ special steel bar rolling mill newly built by Hani tech company has determined the low-temperature rolling process shortly after successfully rolling the first batch of billets, so that users can produce high-quality steel conforming to GB national standards.

The finished bar not only has excellent internal and surface quality, but also achieves high dimensional machining accuracy. For low alloy steel, the low temperature rolling process shows that it can completely change the microstructure of the material within the specified range, so as to improve the mechanical properties and technical indexes of the material. To make good use of this production process, people must clearly understand what it really needs for a specific steel, how to carry out subsequent heat treatment, and what the end use of the product is.

Please contact stella@hanrm.com for a quotation.

And free send inquiry to us.

Email: stella@hanrm.com stellarollingmill@gmail.com

Whatsapp/Wechat:+8615877652925

More News You May Interesting:

Finishing Rolling Mill Process Explanation

Reasons and Solutions for the Piling of Wire Rod Rolling

Characteristics and Quality of Wire Rod

Morgan Wire Rod Mill

Why does the Steel Bar Bend after being Cut by Flying Shear?

Headless Welding Rolling Process

Bar Rolling Mills Water Cooling Technology

How to Improve the Thermal Efficiency of the Reheating Furnaces?

Causes of Surface Cracks in High-Speed Wire Rod Rolling Mill

What is Slit Rolling?

Failure Analysis of Cold Mill Roll

Causes and Solution of Steel Piling-up in High-speed Wire Rod Rolling Mills?

Bar Automatic Counting System

Rolling Mill Pass Design