What are the Failures of the Rolling Mill in Slitting Rolling?

In the slitting rolling of the rolling mill process, various bad phenomena often occur because of the misoperation, which directly affects the quality of the whole piece. Therefore, the corresponding preventive measures should be taken before rolling to ensure that the quality of the tied parts produced is the best.

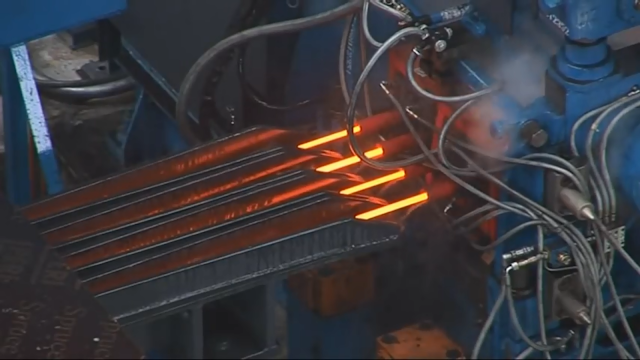

During the whole rolling process, when the fastener leaks out in the high-temperature zone, it is very prone to burr. If it is in contact with the fastener or the temperature rises too fast, there will be the defect of sticking steel. At this time, if the tie piece and its contact, then there will certainly be a very serious situation of sticking steel. Now that the problem of failure has been listed, how should we prevent and solve it?

1. Strengthen the cooling of the discharging tool of the rolling mill so as to avoid sticking steel to the fastener due to high temperature.

2. Reduce the burr of the slitting box in slitting rolling and prevent the leakage of tied parts in the high-temperature area.

3. Periodically check the roll gap of the roll and the value of the roll gap of the slitting wheel, so as to effectively avoid the occurrence of sticking steel.

And free send inquiry to us.

Email: stella@hanrm.com stellarollingmill@gmail.com

Whatsapp/Wechat:+8615877652925

Finishing Rolling Mill Process Explanation

Reasons and Solutions for the Piling of Wire Rod Rolling

Characteristics and Quality of Wire Rod

Morgan Wire Rod Mill

Why does the Steel Bar Bend after being Cut by Flying Shear?

Headless Welding Rolling Process

Bar Rolling Mills Water Cooling Technology

How to Improve the Thermal Efficiency of the Reheating Furnaces?

Causes of Surface Cracks in High-Speed Wire Rod Rolling Mill

What is Slit Rolling?

Failure Analysis of Cold Mill Roll

Causes and Solution of Steel Piling-up in High-speed Wire Rod Rolling Mills?

Bar Automatic Counting System

Rolling Mill Pass Design