The Cold Rolling Mill

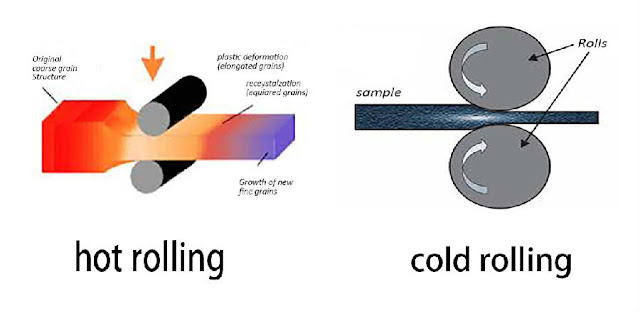

In the article How Many Types of Rolling mill, we know that rolling is divided into two types that are hot rolling and cold rolling according to the different temperatures when metal is rolled. If the temperature is above its recrystallization temperature, then this kind of process is known as hot rolling. If the temperature is below its recrystallization temperature when mentally rolled, the process is called cold rolling.

While this article mainly talks about cold rolling. Cold rolling is fulfilled by making steel strips through plenty of tandem rolling mill stands. And each one of the stands has vertically stacked rolls that are powered by a huge motor to impart high compressive stresses into the strip. While hot rolling, pickled coils fed into the cold rolling mill from an entry-end reel and progressively reduced in thickness in each stand, to achieve the final desired thickness, as the strip exits the last stand. After the last stand, the strip recoiled. At this step, the strip is highly cold and not very useful for most applications. It needs to be annealed to soften the steel and make it more formable.

Another method of cold reduction needs to use of a reversing mill. In this process, the strip is passed back and forth between mandrels on each side of a single or two-stand mill. The strip is reduced in thickness on each pass until the final required thickness is attained. The typical percent cold reduction ranges from 60 to 80 percent; such reducing a hot rolled strip of 0.100-inch thick to a 0.030-inch thickness results in 70 percent cold reduction.

.jpg)