The History Of Rolling Mills

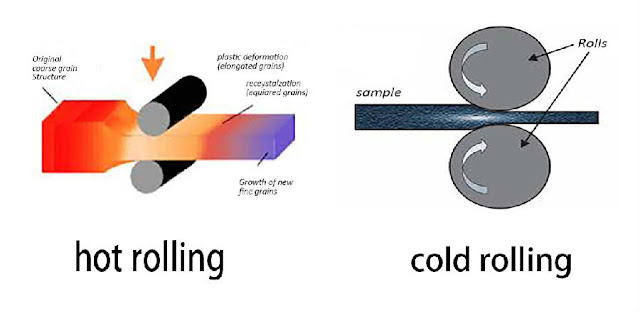

Hot rolling mills and cold rolling mills of metalworking between two or more rolls have been in existence since long before the industrial revolution.

When most people think of a rolling mill, they visualize sizable machinery in ferrous (iron, carbon steel, and stainless steels) and non-ferrous (copper, brass, lead, etc.) integrated or electric arc furnace (EAF) steel mill of today, to small manually cranked rolling devices used at jewelers to reduce the thickness of the precious metal or import a pattern on the surface of the metal to be fabricated into a chain or ring.

Rolling mills have many functions. They can be used to reduce the thickness of material quite accurately (+/-.0001") or compress the material to create a uniform density throughout the strip or impart a surface finish on one or both sides of the material, just to name the most common methods.

Rolling mills are not standard machine toll, nor are they built for stock. They are designed and built to order to specifically accomplish an end product or process.

At one point during the industrial revolution in America, the United States led the world in hot and cold rolling, plate mills, slabbing mills, and blooming mills. Companies such as Mesta, United, Blaw-Knox, Lewis, Continental, and Bliss were attributed to building some of the largest rolling mills in the world before World War II. In fact, Mesta and United pioneered the rolling process to reduce very thick as cast slabs into the plate, the plate into hot rolled coils and cold rolled coils.

Many of these old mills are still running today as a result of upgraded electrical and hydraulic systems, including hydraulic screwdowns, hydraulic roll bends, and tension control.

Please contact stella@hanrm.com for a quotation.

And free send inquiries to us.

Email: stella@hanrm.com stellarollingmill@gmail.com

Whatsapp/Wechat:+8615877652925