Selection of Rolling Mill Rolls in Long Products Rolling Mill

Roll is the core part of the rolling mills. The use of roll involves the selection of rolling mill type, the preparation of roll, the maintenance, and periodic repair in the rolling process, which are all factors affecting the productivity, product quality and production economy of the rolling mill. Because the rolling process is a continuous process, operators need to constantly check the roll condition to make the products meet the user's requirements for more stringent tolerance and surface quality. In order to make the products continuously competitive, it is necessary to continuously require the mill operators to reduce the production cost, that is, to improve the rolling speed, the production flexibility of the rolling mill, and to reduce the consumption of rolls.

There are many kinds of rolling mills for producing long products. Therefore, the selection range of rolling mill type, roll material, and roll size is very wide. At the same time, the rolls selected by different rolling mills are also different, so it is necessary to select rolls according to the production requirements.

Long Products Rolling Mill

In order to increase productivity and improve product quality, it is necessary to fully understand the type and configuration of various rolling mills before selecting suitable rolls.

Bar and Small Section Rolling Mills

Generally speaking, both ingots with a size range of 80-150 mm and continuous casting billets with the same size range can be used in bar and small section mills to produce small sections and bars. The initial feeding temperature of raw material for bar and small section mill is 1200 ℃, and the mill can be produced in a semi-continuous or full continuous way. Continuous rolling mill is the development trend at present. There are roughing mill, medium rolling mill, and finishing mill stand. Roughing stands are arranged in horizontal/vertical order, which mainly depends on product composition. Intermediate stands and finishing stands can be either vertical or horizontal. For the bar, the rolling mill consists of more vertical stands, while for other small profiles, the horizontal stand is often used.

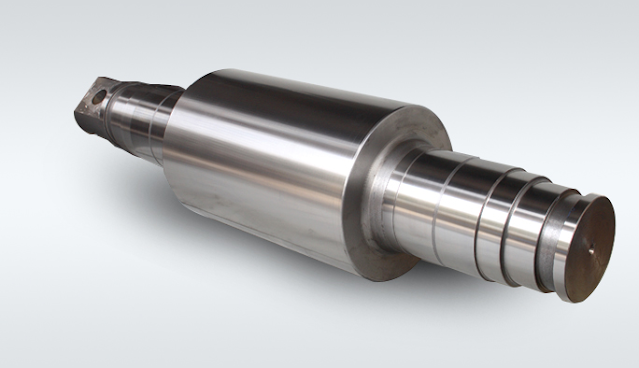

In the small section rolling mill, the diameter of the roll is 300-600mm and the length of the roll body is 700mm according to the feed material and the final product size. For the tolerance of the product, the user generally requires one-third of the international tolerance standard, and the product should have a good surface finish. For small sections products, the rolling speed of the rolling mill is from 12m / s to 20m / s, while for the bar mill, the rolling speed has increased to 36m / s.

Wire Rod Mill

Wire rod mill has roughing mill stand and intermediate mill stand similar to small profile mill. These mills are generally designed to carry out slitting rolling up to 4 lines simultaneously, compared with small section mills with two-line rolling. However, the current development trend is to use single line high-speed rolling. Modern wire rod mills generally have 8-10 untwisted stands arranged at 90 ° angle to each other in finishing mills.

At present, the roll diameter of the wire rod mill is limited to 200 mm. The rolling speed can be as high as 140m / s.

Medium Section Mill and Large Section Mill

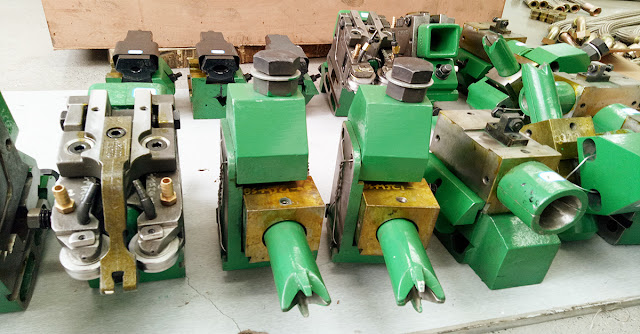

After the roughing stand, the medium section mill has two sets of continuous stands. According to pass design, the continuous rolling mills can be arranged either horizontally or vertically. For section steel and channel steel with the parallel edge, the universal rack is also provided. When rolling other profiles, the universal stand can be replaced by a horizontal stand. The rolls of the horizontal stand have a deep pass, but the universal stand does not.

A larger diameter horizontal roller determines the shape of the profile, while a smaller diameter opposite roll is used to roll the edge. Good surface finish and dimensional tolerance can be obtained when the blank passes through the finishing rolls of traditional stand and universal stand.

Selection of Rolling Mill Rolls Parameters

Steel Grades to be Rolled

The type of steel to be rolled is the key factor to select the roller, and its anti-deformation ability changes with the different chemical composition of the billet, which is mainly reflected in the deformation load and change in each stage of rolling. The roll must be selected according to the determined strength and hardness.

Rolling Mill Layout and Pass Design

The position of the stand in the production line and the design of the pass has a great influence on the selection of the roller. According to the position of the stand, the stress mode and performance of the roller can be greatly changed. This is due to the very different stress modes of the rolls applied to the roughing and finishing stands, resulting in the expected changes in roll performance. In addition, the time interval between one blank and the next and the productivity of the mill also have a great influence on the selection of rolls. It can be observed that roll bending and torsional stress combined with high rolling pressure are the factors determining the selection of rough steel stand roll. However, in finishing stands, hardness, wear resistance, and surface quality are the key factors for roll selection.

Friction Between Rolls and Billet

Friction plays a very important role because of the difference between the circumferential speed of the roll and the billet speed, especially at low speed, such as blooming mill and roughing stand. Therefore, the relevant data create conditions for the proper selection of rolls for specific stands.

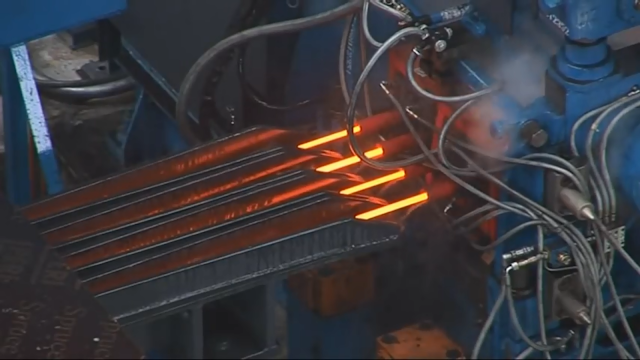

Hot Condition

The hot state of the roll and the rolled stock is also very important. The main reason is that the temperature of the roller is much lower than that of the rolled blank, so the roller is vulnerable to high thermal shock in a short time, which leads to the formation of burning cracks on the surface of the roller, and further diffusion to form fatigue cracks. Therefore, the selection of roll should consider the minimum crack generation and diffusion under rolling conditions.

Rolling Mill Rolls Cooling

The effectiveness of the roll is also related to the arrangement of the mill coolant. The thermal conductivity of roll material has a great influence on the cooling of rolls. The higher the heat conductivity of roll material is, the higher the requirement of effective cooling is. The main reason is to avoid the occurrence of burning crack and reduce the service life of the rolls.

Roll Selection According to Mill Type

The selection of roll is very skillful, and the experience of mill operators plays a decisive role in the selection of roll.

Bar and Small Rolling Mill

The requirements of this kind of rolling mill are as follows:

1) good bending strength relative to impact;

2) uniform hardness of roll;

3) high wear resistance;

4) better-burning crack resistance.

Rolls of various materials can be used in this kind of mill, mainly depending on the design of the mill and the experience of the operator. The rolls that can be used are:

Nodular cast iron roll: in a continuous bar rolling mill, nodular cast iron roll is used for roughing mill stand and finishing mill stand. For roughing stands, molybdenum alloyed, annealed pearlitic cast iron rolls are used. The roll hardness value depends on the actual production conditions of the mill. If the burning crack resistance is mainly considered, the softer roller can be selected, while the harder roll should be given priority to the wear resistance, which can be used in the traditional frame and cantilever frame. The service life of these ductile iron rollers is longer than that of steel rolls.

For the intermediate frame, the general choice of pearlite or needle crystal ductile iron roller. The current trend is to use chromium alloyed and centrifugal cast acicular crystal nodular cast iron roll, and the service life is better than the traditional infinite cold hardening roll. In some small mills, alloyed ductile iron rolls are only used in roughing stands and intermediate stands. This is because these rolls are required to withstand the maximum load and therefore cannot be used in finishing stands where surface finish is the main consideration.

Alloy infinitely chilled cast iron rolls: these rolls show good wear resistance and improved bite in performance. In order to adjust the hardness of the roll, alloying elements such as chromium are added to increase the hardness of the roll. In addition, the surface finish of the products with these rollers is very good. In many bar mills and small section mills, these rolls are used in finishing stands. However, in some steel mills, such rolls are also used for intermediate frames. The tensile strength of the roller is 20 ~ 30kg / mm2.

Alloy cast steel rolls: Generally speaking, these rolls are mainly used in roughing stands with tensile strength ranging from 50 to 65kg / mm2. In some small mills, alloy cast steel rolls are also used in intermediate stands and finishing stands.

High-speed steel casting roll: there is fe-c-cr-w-mo-v alloy in high-speed steel casting roll. These rolls are produced by centrifugal casting. They have a high alloyed shell and spheroidal graphite core, so they have good wear resistance and mechanical properties. Their toughness is equivalent to that of alloy infinite chilled cast iron rolls. These rolls show good wear resistance, thermal fatigue resistance, and spalling resistance.

High-speed steel casting roll is mainly used in finishing mill stand and shows satisfactory results. It can also be used for finishing passes where the mill speed is less than 7 m / s, which is very difficult for the centrifugal carbonized roll to work. Compared with the centrifugal carbonization roller in the same application, the yield strength of high-speed steel casting roll is better, and the tensile strength reaches 108kg / mm2. However, these rolls require strong cooling to ensure that the temperature of the rolls does not exceed 60 ℃.

Wire Rod Mill

The requirements for the rolling mill rolls of wire rod mill are:

1) uniform hardness on roll thickness;

2) high wear resistance;

3) high resistance to burning. The roll used in a wire rod mill is very wide, which mainly depends on the production process, wire rod mill layout, and design.

Nodular cast iron roll: molybdenum alloyed ductile iron roll is mainly used in roughing stands, with good resistance to burning and wear. Because the diameter of the wire rod produced by wire rolling mill is very small, the minimum wire diameter is only 5.5mm, and the surface finish is a very important index. Therefore, the ductile iron roll can not be used in intermediate stand and finishing mill stand.

Alloy infinitely chilled cast iron rolls: these rolls can be used in intermediate stands, which show good wear resistance and improved bite in performance. In order to adjust the hardness of the roller, alloying elements such as chromium are added to control the hardness of the roller. The surface finish of the product with this kind of roller is very good. In many bar mills and small section mills, these rolls are used in finishing stands. The tensile strength of the roller ranges from 20 to 30 kg / mm 2.

Centrifugal casting tungsten carbide roll: at present, the finishing rolling speed of many wire rod mills has exceeded 120m / s, so the centrifugal casting tungsten carbide roller is used for pre-finishing mill stand and finishing mill stand. This type of roll contains hard tungsten carbide grains imbedded in a soft metal matrix (usually cobalt, nickel, or alloys of these metals). When the rolling speed exceeds a certain value, special attention should be paid to the roller, because the cooling of the roller may not be enough to prevent the hot cracking. For a certain rolling speed, the roll must exhibit good hot cracking resistance by having higher fracture toughness and lower rigidity. This performance can be achieved by selecting more than 25% of the bonded elements (cobalt, nickel, or the alloy of these metals combined with chromium). At higher rolling speed, the contact time between roll and blank is shorter, so hot cracking will not play an important role, and the increase of roll wear rate of the last stand should be solved. Because the wear resistance is mainly related to the content of tungsten carbide and bonding elements, the wear resistance can be improved by selecting the roller with lower bonding element content. In addition, the pH value of the coolant should be kept at about 8.5 and CaCO3 should be at 300 ppm. After cleaning, the roller should be placed in a dry place because the residual water will cause rust and corrosion of the roll.

High-speed steel casting roll: this kind of roll can be used in the finishing stand of wire rod mill. The tensile strength of the high-speed steel roll is 108kg / mm2. However, the rolls require strong cooling to ensure that the temperature does not exceed 60 ℃.

Large Section Steel Rolling Mill and Rail Beam Rolling Mill

The requirements for the rolls of this kind of rolling mill are as follows: (1) good wear resistance, especially the side wear resistance; (2) good fracture strength, which can withstand strong impact and uniform hardness on the roll thickness.

Alloy cast steel roll: the selection of this kind of roll is mainly due to the hyper eutectic composition in the steel, which improves the wear resistance and hot cracking resistance of the roll, but slightly reduces the strength.

Ductile iron roll: in these mills, the ductile iron roll is used for intermediate stand and finishing mill stand.

Roll Management in the Production Process

In the production process, the improper operation should be avoided or minimized so as to obtain satisfactory roller performance.

The minimum roller overload: since each pass is designed for a specific blank, any overload can cause excessive stress on the roll. Therefore, the low temperature of billet should be avoided by monitoring to ensure that it has a suitable temperature.

Reduce the friction and wear rate: even if the hardness of the roller is appropriate, the wear of the roller may increase due to the uneven temperature of the blank, improper cooling arrangement of the roll, and the low-temperature oxide entering the pass during rolling. It is necessary to ensure that the billet has proper heating and soaking to avoid rolling interruption.

Make sure that the rolls have proper cooling to minimize work hardening: pay attention to the distribution of cooling water in advance. The temperature of the rolls should be kept in a certain range as far as possible, and there must be no chilling. When the high-temperature billet is rolled by the cold roll on the rolling mill, the work hardening layer will be formed on the roll and hot crack will be formed. Therefore, when the rolling mill is not working, the cooling water valve should be closed. If the cooling water is open and the rolling mill is shut down, the roll should be kept running to avoid cooling part of the roll and not cooling the other part. Uneven cooling is one of the causes of roll cracking. In addition, rolling without cooling water will also cause roll cracking. It must be kept in mind that the distribution and pressure of the cooling water used to cool the rolls mainly depend on the type of roll used.

Avoid excessive rolling: this can be achieved by replacing long-term used rolls with new ones.

Economical use of Rolling Mill Rolls

For a given production process, the economical use of rolls is ensured by proper selection of rolls for specific mills. In order to prolong the service life of rolls, after careful inspection and modification of auxiliary facilities such as bearing pedestal and upper roll screw, larger diameter rolls can be used in some mills.

In a word, the selection of rolls is aimed at the roller application situation to make it meet the production requirements. The selection of roll should consider the size, shape, type, temperature of rolled material, rolling speed, size and size of roll, the efficiency of cooling water and its chemical composition, maintenance method of the roll, and detection method of the roll. In addition, careful management and maximum use of rolls are also important factors for prolonging the service life of rolls and improving their performance.

Whatsapp/Wechat:+8615877652925

Website: https://www.hanrm.com