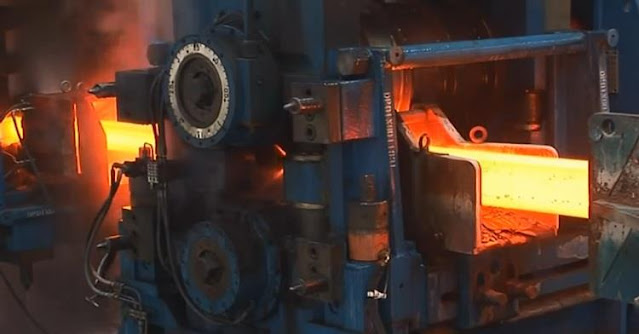

What Should The Rolling Mill Need To Pay Attention To During The Shutdown?

In the production process of the rolling mill, what should be noticed after the rolling mill is shut down when there is a downtime overhaul or an unexpected situation?

1. After the rolling mill stops, stop the feeding of steel, and take the gas cutting and cutting out of the online rolling parts to avoid the stress on the rolls and cause damage.

2. If the rolling mill needs long-term shutdown, the best method is to open the lubrication system to keep the main bearing lubricated, and then close it in to avoid dust and debris entering the bearing.

3. Cut off the power supply of the rolling mill and auxiliary equipment.

4. Drain the water in the cooling tube to avoid freezing the cooling water pipe when it is cold.

5. Protect the lubrication system, motor, air clutch and slow drive from dust, but not tightly sealed to avoid moisture accumulation. Use a small heater or protect the bulb to prevent moisture buildup.

6. Place bagged desiccant in all control and electrical panels to prevent moisture build-up and safely seal the control panel.

The above need to pay attention to is that the rolling mill production enterprises need to pay special attention to it. Only when the rolling mill is under maintenance, the rolling equipment can better complete the production task during the production period, improve the rolling efficiency and extend the usage time of rolling mill.

Since 1989 Hani Tech has been always involved in design, engineering, manufacturing and installation of complete hot rolling mill plant for long products (re-bars, SBQ bars, wire rod, small and medium sections), as well as revamping and upgrading of existing plants.

Hani Tech is the one-stop manufacturer & supplier able to design, manufacture, install and commission your hot rolling mill plant from A to Z.

Please contact stella@hanrm.com for a quotation.

And free send inquiry to us.

Email: stella@hanrm.com stellarollingmill@gmail.com

Whatsapp/Wechat:+8615877652925

No comments:

Post a Comment